Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

In March 2025, the world’s leading policymakers gathered in Dubai for *Renewables 2025*, a high‑profile summit where governments, industry giants and NGOs pledged to cut global emissions by 70 % by 2050. The central theme was the rapid electrification of transportation and industry—electric buses, shuttles, heavy‑duty trucks, and even autonomous delivery robots were set to dominate the streets of tomorrow. Amid the applause for massive subsidies and new regulations, one industrial component quietly stood out as the backbone of this green revolution: the gear motor, also known as a reducer motor.

At first glance, the idea of a gear motor—a compact assembly of gears, a motor, and a shaft—seems far removed from global climate agreements or political pledges. Yet, the gear motor’s humble design is actually at the heart of every electric vehicle (EV) and many automated industrial systems now racing towards zero‑emission standards. This article explores how the gear motor’s engineering excellence dovetails with the lofty goals announced at *Renewables 2025* and why these motors are poised to become even more crucial in the forthcoming decade.

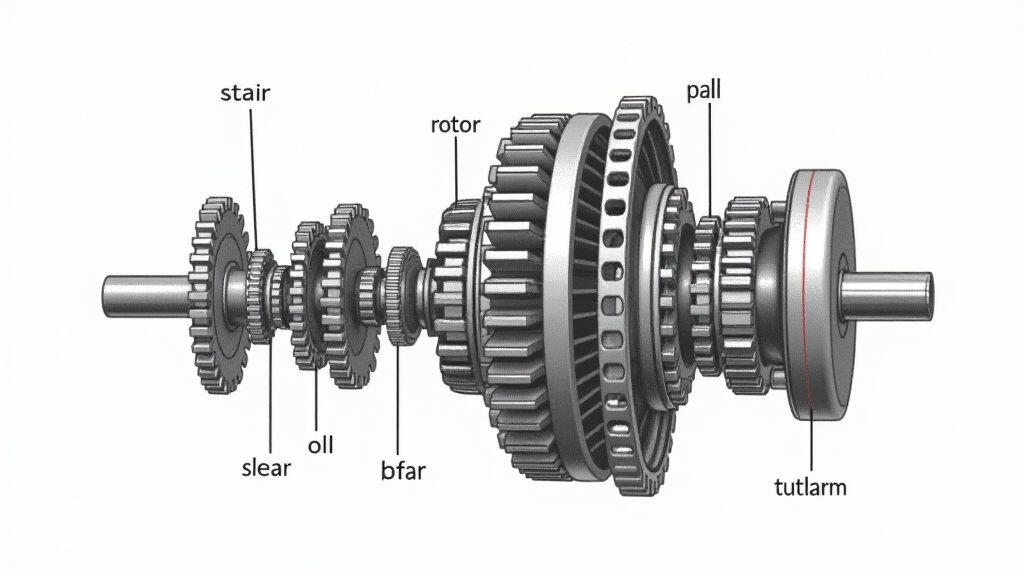

Unlike a conventional electric motor that delivers high RPM but low torque, a gear motor integrates a gear reducer directly into the motor housing. This combo translates the high speed of an electric motor into the low‑speed, high‑torque output needed for heavy loads, all while keeping the unit compact and sealed. The result? A reliable, low‑maintenance component suitable for harsh industrial environments, road traffic, and robotic applications.

One of *Renewables 2025*’s landmark moments was the announcement of a $15 billion subsidy package to replace diesel pickups and delivery vans with their electric counterparts. Companies like Tesla, Rivian, and emerging startups each showcased battery‑powered trucks capable of carrying 20 tonnes of cargo. For these trucks to achieve the required payloads, they must transmit power efficiently from the battery to the wheels: that’s where gear motors come in. By housing a gear reducer in the motor itself, manufacturers reduce the need for separate transmission units, cutting weight and complexity.

Because gear motors can maintain torque across wide speed ranges, they are ideal for scenario‑driven demanding tasks: a delivery van takes a sudden stop at a busy intersection or climbs a steep grade. The motor’s inherent torque compensation means the operator never experiences a loss of power—crucial for safety and consumer confidence.

With the global shipping market seeing a projected 20 % jump in micro‑delivery by 2030, a new wave of autonomous robots—sometimes called last‑mile drones—are emerging. These autonomous units rely heavily on small, high‑efficiency gear motors to drive their wheels, lift platforms and handle complex movement patterns.

Comparatively, a typical gear motor’s power density exceeds 200 W per cubic inch, while still producing torque above 10‑30 Nm. This makes them lightweight enough for a 200‑kg robot but powerful enough to negotiate uneven sidewalks, crosswalks and even small human obstacles. Their sealed construction ensures longevity in wet and dusty conditions, eliminating the extraneous maintenance that can cripple automation deployment.

Gear motors are not only relevant to road transport. The shift toward renewable energy generation—solar farms, wind turbines, and tidal power—demands robust gear technology for mechanical drives. For instance, high‑speed DC generators used in offshore wind turbines often incorporate gear reducers to match the generator’s optimum RPM to the grid’s standard frequency, reducing the size of power electronics and cut costs by 3‑5 % per turbine.

Additionally, gear motors enable the precise positioning of solar panels and wind turbine blades, ensuring optimal energy capture throughout the day. The result: higher efficiency and lower operational costs, translating into cheaper green electricity for industrial users and consumers alike.

Industry analysts predict that the global gear motor market could grow to $10 billion by 2030, with a CAGR of 6.5 %. The primary growth drivers will be:

Parallel to market growth, manufacturers are developing next‑generation gear motors that push the limits of lightweight materials—carbon fiber composites, aluminum alloys—and advanced sealing technology. Furthermore, integration of smart sensors and IoT connectivity means gear motors can now report real‑time torque, vibration and temperature data, enabling predictive maintenance that saves millions over their lifecycle.

Conventional internal combustion engines (ICEs) consume vast amounts of lubricants and generate significant CO₂ emissions. Gear motors offer a cleaner alternative: electric motors have a near‑zero fuel use at the point of operation, and when paired with clean electricity grids, the CO₂ footprint drops dramatically. Additionally, gear motors are typically more durable than ICE transmissions, meaning fewer replacements per vehicle or machine—less manufacturing waste and fewer emissions.

When considering the entire lifecycle—from raw material extraction to end‑of‑life recycling—gear motors offer a favorable carbon profile. Many modern gear motors incorporate recyclable materials and designs that facilitate disassembly, further reducing the environmental load.

The *Renewables 2025* summit highlighted an urgent call to action: accelerate the transition to a low‑carbon economy. While policy, finance, and culture all play essential roles, the indispensable behind‑the‑scenes hero that will power thousands of electric cars, autonomous robots and renewable infrastructure is the gear motor. Its compact, efficient, and resilient design enables electrified systems to run reliably, meet regulatory demands and stay cost competitive.

As technology matures—through advanced materials, embedded sensors and smarter integration—gear motors will become even more central to the industries that shape our future. Whether boosting the torque of a delivery van or fine‑tuning the pitch of a wind turbine blade, the humble gear motor is what turns the gears, quite literally, toward a cleaner, greener planet.

Leave A Reply

Your email address will not be published. Required fiels are marked